Showroom

Orifice plate flange assemblies are precision-engineered flow measurement devices used in industrial pipelines. They provide accurate differential pressure readings for fluid and gas monitoring. These assemblies ensure leak-proof performance, secure installation, and long-term reliability, making them ideal for oil & gas, chemical processing, and power plants.

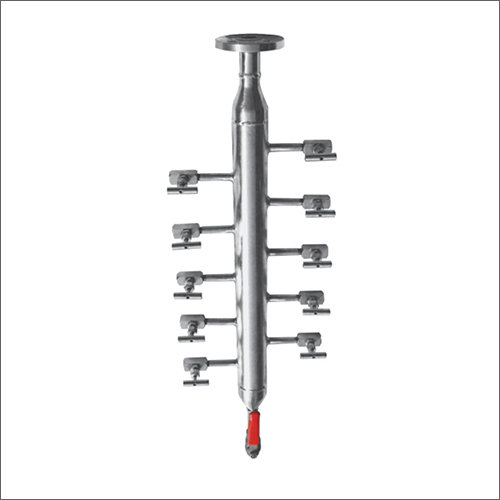

Air headers are durable distribution manifolds designed to supply compressed air from a single source to multiple outlets. They ensure safe, reliable, and efficient pneumatic operations across industrial systems. These headers offer excellent pressure handling, corrosion resistance, and structured air control for plants, refineries, and automation environments.

Flow nozzles are advanced differential pressure flow measurement devices used for accurate and stable fluid and steam flow monitoring. They maintain high performance under harsh operating conditions, offering minimal wear and pressure loss. These nozzles are widely used in pipelines, power plants, and high-velocity steam applications.

Manifold valves provide compact and efficient control for pressure instruments, ensuring precise isolation, calibration, and equalization. These valves are engineered for high-pressure industrial environments and offer leak-tight sealing, corrosion resistance, and easy maintenance. They are commonly used with pressure gauges, transmitters, and flow measurement setups.

Venturi tubes are reliable flow-measuring devices that work on differential pressure principles, ensuring highly accurate readings for gases, liquids, and steam. They minimize energy loss, handle high flow rates, and operate efficiently with low maintenance. These tubes are widely used in refineries, chemical plants, and water systems.

Skid manifold systems are compact, factory-assembled units designed for streamlined fluid and gas distribution in industrial operations. They provide efficient flow control, reduce installation time, and ensure operational reliability. These systems deliver safe, modular, and space-saving solutions for oil & gas, chemical, and utility sectors.

Needle valves are precision control devices designed to regulate fluid flow with accuracy. They offer smooth throttling, leak-free performance, and excellent pressure endurance. These valves are suitable for instrumentation, sampling lines, and high-pressure systems across oil & gas, chemical, and laboratory applications.

Globe valves provide precise shut-off and flow regulation in process lines. Designed for durability and smooth operation, they handle pressure variations efficiently. These valves are widely used in steam, water, and chemical applications, offering dependable sealing, corrosion resistance, and easy maintenance in industrial systems.

Gauge cocks are manual control valves used to isolate and protect pressure gauges. They ensure safe gauge operation, pressure release, and accurate readings. These valves are durable, compact, and leak-proof, making them suitable for industrial boilers, instrumentation lines, and critical pressure monitoring systems.

Grinder plates are heavy-duty cutting components used in industrial grinding and processing equipment. They ensure efficient material breakdown, consistent output, and smooth operation. These plates are crafted for wear resistance and durability, making them suitable for food processing, recycling units, and heavy-duty grinding applications.